CNC Machining Services

Get quality custom parts for prototyping and production, fast and cost-effective.

What is CNC Machining?

Advantages of CNC Machining

Capable of creating a wide range of different shapes

High precision

High repeatability & scalability

Wide range of material options

Achievable mechanical properties

CNC Machining FAQs

The CNC milling process involves a rotating tool that carves away excess material from a stationary workpiece.

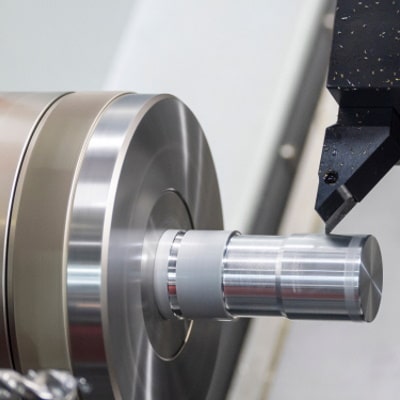

CNC turning uses a rotating workpiece, typically used to make cylindrical parts.

The CNC milling process involves a rotating tool that carves away excess material from a stationary workpiece.

CNC turning uses a rotating workpiece, typically used to make cylindrical parts.

Prices start around $65, but vary based on complexity, quantity and lead time. The best way to find out is to submit a 3D CAD model and get an interactive quote with design for manufacturability (DFM) feedback. Because we use proprietary software and automated fixturing processes, there are no upfront non-recurring engineering (NRE) costs. This makes purchasing quantities as low as 1 to 200 parts cost-effective. Prices compared to 3D printing are comparable to somewhat higher, but machining offers improved material properties and surfaces.

CNC machining is widely used across industries. It is common in aerospace, automotive, consumer electronics, robotics, agriculture, and other fields that frequently use metal parts. It is also widely used in medical devices, household goods, energy, oil and gas, and other consumer applications. It is one of the most common manufacturing processes in the world.

Why Choose Us As Your Manufacturing Partner?

Powerful Network Capacity

Access the production capacity of over 5,000 vetted manufacturing partners with comprehensive capabilities and certifications in China. The network is expanding daily.

We are certified to ISO 9001:2015, ISO 13485:2016, and AS9100D. In addition, we offer CoCs, SGS, RoHS, material certifications, full dimensional reports, finishing certifications, inspection reports, and hardware certifications. First Article Inspection Program is also available upon request.

Dedicated Customer Support

Your account manager will be at your service from the first contact to ensure quality parts are delivered to you on time. We offer free expert design for manufacturability (DFM) analysis, highlighting potential problems and providing immediate solutions and money-saving tips.

Competitive Pricing

Our national and local knowledge of manufacturing capabilities in China gives us an edge in choosing the most suitable yet cost-effective suppliers for your projects.

Time-approved Experience

Our engineers have up to twenty years of experience in manufacturing. We served satisfied customers from over thirty countries in the last five years.

How It Works

Getting your parts with an easy 6-step process

Submit Your Inquiries

Get a Quote with Free DFM

Place an Order

Review Samples

Kickoff Production

Recieve Your Parts

Ready to Get Your Project Started?

Try our manufacturing services. We are committed to helping you fulfill your projects, from prototyping to production.